North Outfall Sewer (NOS) 10

⸻

PROJECT details

Client: City of Los Angeles

Location: Los Angeles, CA

Capabilities: Rehabilitation, Value Engineering / Design Build, Heavy Civil

Services: Bypass Pumping, Sliplining, Cement Mortar Lining

Contract Value: $33,519,257

-

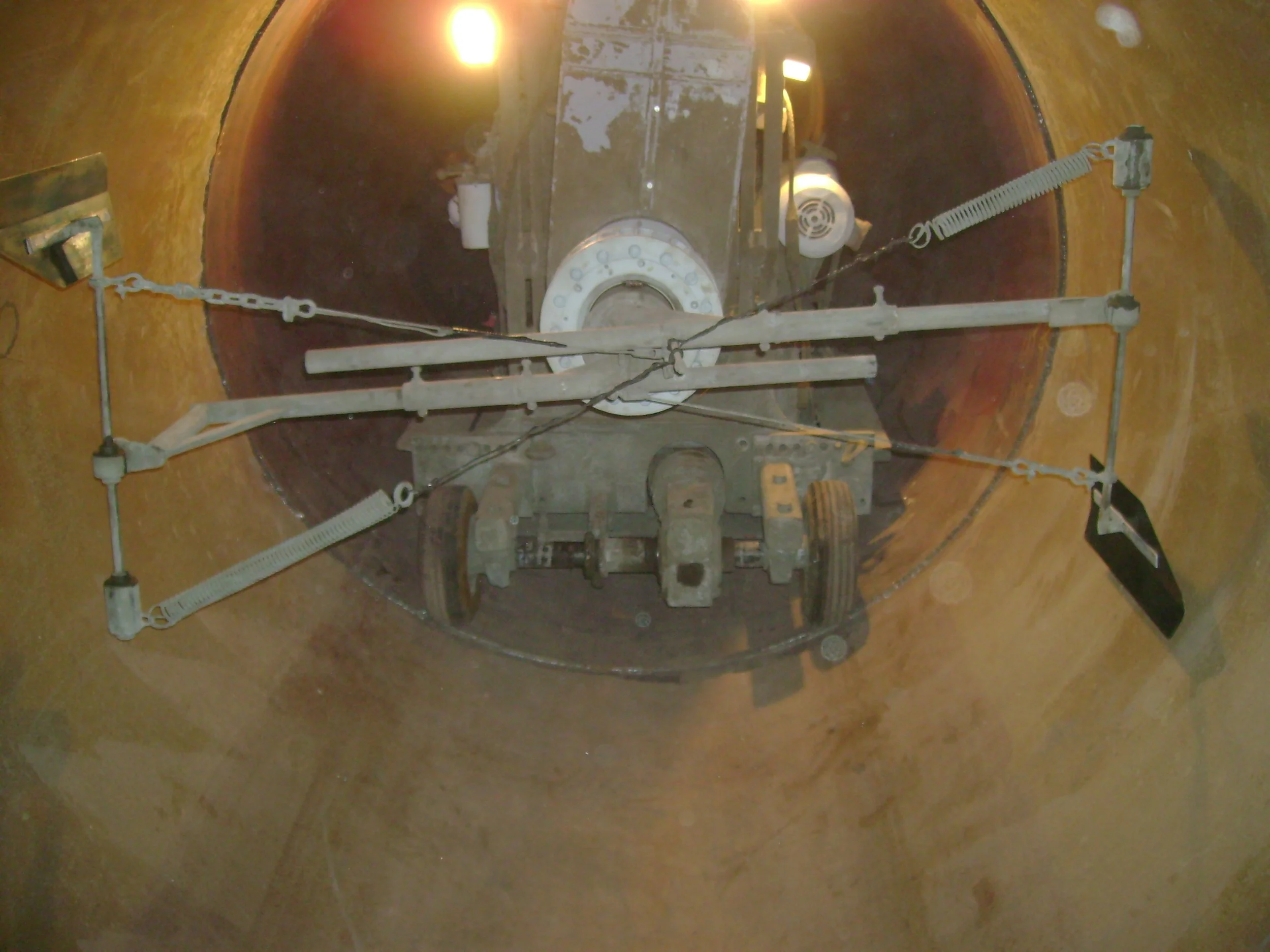

This project involved sliplining 5,013-feet the semi-elliptical, concrete North Outfall Sewer (NOS) from the Intersection of 101 Freeway and Mission Road, along the Union Pacific Railroad right-of-way, and to 256-feet north of the intersection of Gibbons Street and Cardinal Street. This segment of the NOS was originally built in 1929 and consists of 3,548 feet of 54-inch and 1,426-feet of 48-inch concrete sewer. It also includes a 39-foot monolithic 108-inch storm drain and NOS structure.